Do you use traditional circuit boards for assembling different electronic components and connecting them electrically? In that case, how much time it is required to assemble the entire circuit manually?

Your silence proves that the entire process is very time-consuming.

To reduce time-consumption, to scale down your effort, and to generate mass production, PCB or Printed Circuit Board came into existence.

Printed circuit boards are high in demand nowadays. With the advancement in technology and the rise in demand for electronics, manufacturers are profoundly using PCB keeping the traditional circuit boards aside. As a consequence, the PCB assembly factory is gaining high importance.

Now the question is why? Why people are preferring to order PCB instead of hand-assembled circuit boards? Any idea?

Here in this blog, we will justify the reason by presenting a few benefits offered by PCB. Are you curious to know more about PCB? Dive into the blog and get an insight.

How PCB can benefit your business? Check out the 4 reasons.

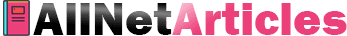

- Lowering production cost: Nothing can be more beneficial for a manufacturer than making a profit from lowering down the production cost. Have you ever thought about this while using traditional circuit boards? Probably, not. But with PCB you can really experience the low-budget production of assembled circuit boards.Unlike the traditional circuit board designers, PCB designers take no time to assemble the circuit using exclusive software. From assembly to production, all the things are done digitally, thus requiring less effort and production cost.

- Enhancing the consistency: Errors and mistakes are quite common when you are using traditional circuit boards for assembling electronic components. However, with this error, you can never provide an accurate output. This what hampers the quality of the circuit board making it difficult to attain the optimum result.However, with PCB you can feel free to ensure consistency. Printed circuit boards reduce the risk of errors and delays, offering accurate results to the viewers. To avoid errors, these boards make use of smaller components that are soldered correctly without any mistakes.

Are you looking for accurate and authentic results? Don’t forget to order PCB. - Improve mass production: PCB assembly in comparison to hand-assembled circuit boards require less time, effort, and production costs. All these factors are responsible for generating PCB at high volume. Agree or not? And the best thing about these PCB is you get the chance to produce a large volume of PCBs at a cost-effective rate.

- Offer easy-to-repair convenience: Have you ever find it easy to repair or diagnose a hand-assembled circuit board? Probably, your answer will be a big no. Hand-assembled circuit boards never give you the convenience to analyze the problem and repair it with ease.However, the picture changes when it comes to printed circuit boards. No matter how complex the circuit is, it is easy to find the failed components and replace them with the right ones. Well, this is possible because the electronic components and their polarities are clearly visible on the printed circuit boards.

The Bottom Line

No doubt, hand-assembled circuit boards result in slow production, high time-consumption, and low-quality features. Whereas, you can appreciate all these factors when you order a PCB from a PCB assembly factory.

Printed circuit boards are now available at a much affordable rate. Those who prefer not to buy these automated circuit boards because of its high price must think of any other strong reason to say “no” to it.

So, friends, are you heading to buy PCB online? Search over the web with the keyword and find the best dealer that offer high-quality PCB at a reasonable rate. Don’t forget to research!